In the weaver's hands, the wool stretches across the tensioned warp threads. The wooden beater taps down each row with a quiet rhythm that fills village workshops from Kashmir to Tabriz. But how long does this meticulous craft actually take? The creation of a handmade rug unfolds not in days or weeks, but in months to years - its timeline governed by knot density, technique, materials, and the complexity of its design.

How long does a handmade rug take?

A handmade rug typically requires anywhere from several months to multiple years to complete. This extended timeline exists because every single knot is tied individually by hand, with the total time primarily determined by the sheer number of knots in the piece.

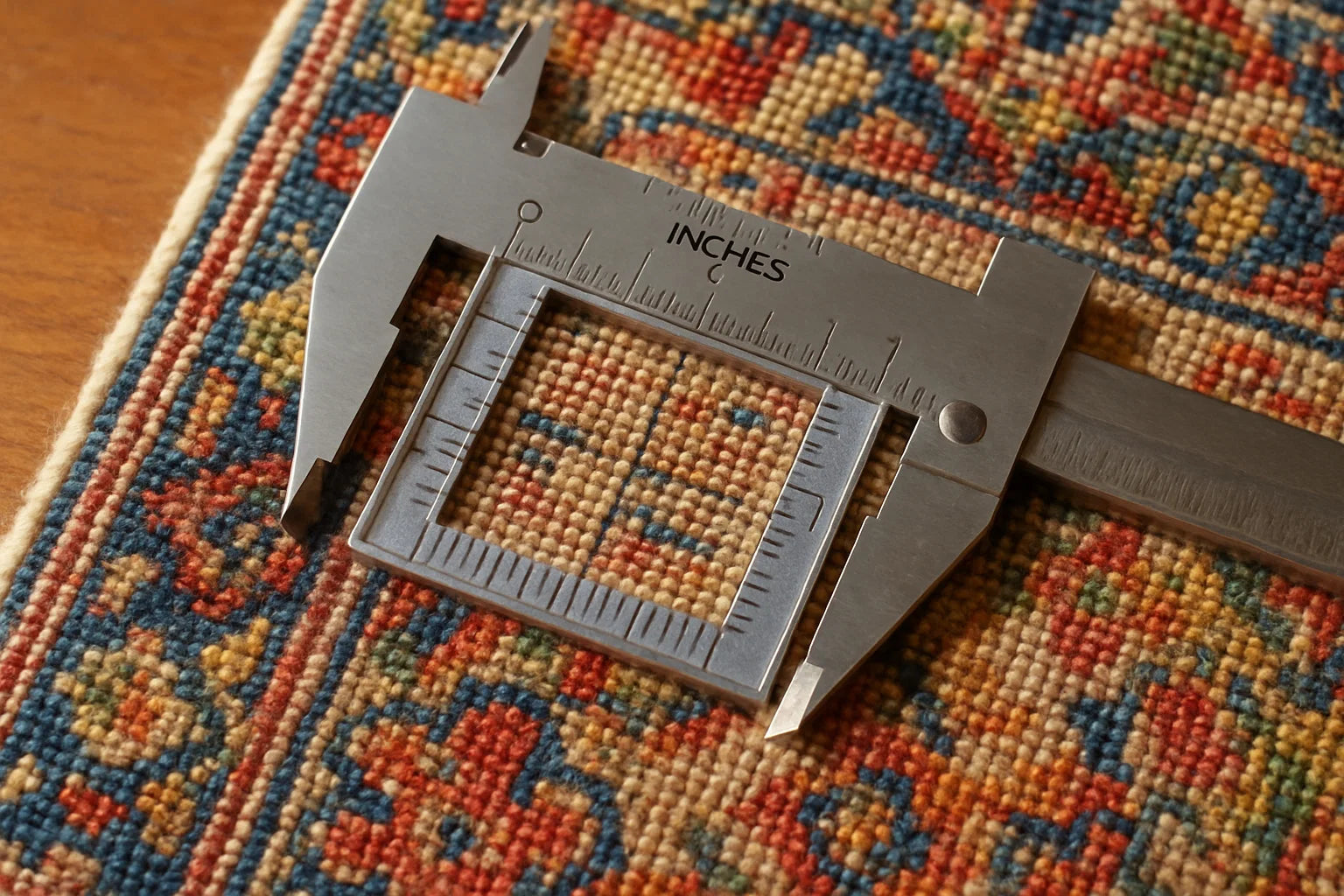

A fine Persian rug with a density of around 320 knots per square inch (KPSI) and a size of about 6 square metres contains roughly 500,000 knots per square metre, adding up to around 3 million individual knots in total.

For perspective, for a single weaver, this translates to around 300 working days of consistent labour. While multiple weavers working together on a single piece can reduce the calendar time, the total number of labour hours remains essentially the same.

What drives rug weaving time

Several key factors determine how long a rug takes to create:

-

Knot density serves as the primary driver of labour hours. A fine rug might contain 350,000 to 650,000 knots per square metre, while an ultra-fine piece (typically the most intricate and exclusive of silks) can exceed 1 million knots per square metre.

- Pattern complexity significantly impacts weaving speed. Intricate curvilinear patterns with medallion centres and detailed borders require more concentration and frequent pattern consultation than simpler geometric or open fields.

- Materials selection introduces variation in preparation time. Hand-spun wool demands careful combing and spinning, while incorporating fine silk requires additional processing steps.

- Dye approach can extend timelines considerably, often taking a few weeks to prepare. Natural dyeing involves multiple cycles of dyeing, sun drying, and resting periods to achieve depth and stability of colour.

- Loom size and ergonomics affect weaver efficiency, with larger looms requiring more physical movement and sometimes multiple artisans working in coordination.

These factors interact in complex ways. For instance, a large rug with moderate knot density might require similar hours as a smaller piece with extraordinarily fine knotting.

Technique and pattern: from knots to motifs

The weaving method has a major impact on production time. Hand-knotted pile rugs are slow to make, as each knot must be tied individually around the warp threads before being cut. In contrast, flatweaves like kilims move faster as they lack pile and use a continuous weft thread passing through the warp.

Knot type itself affects pace. Persian (asymmetrical) knots allow for greater pattern detail but can be slower to execute than Turkish (symmetrical) knots in certain designs. Pattern language equally shapes the timeline: curvilinear arabesques with their flowing, naturalistic forms demand finer gauges and precise execution, slowing progress compared to more angular, rectilinear motifs found in geometric tribal designs.

Border complexity particularly affects overall timing. Multiple nested borders with alternating motifs require frequent pattern changes and careful alignment across the rug's perimeter, whereas simpler border treatments allow more continuous work rhythm.

Materials and dye work: the quiet time costs

Before the first knot is tied, significant hours are invested in material preparation. Fine hand-spun wool requires careful sorting, cleaning, combing, and spinning to ensure consistent thread diameter and strength. Introducing silk elements demands even more upstream preparation: degumming the raw silk, selecting consistent filaments, and achieving proper tensile strength.

Natural dye work introduces its own timeline. Unlike synthetic colours mixed to formula, natural dyes involve iterative processes - multiple dye baths, careful sun drying between applications, and resting periods to allow colours to stabilise. Achieving consistent, light-fast colours from plant and mineral sources requires patience and expertise.

This upstream investment yields the subtle colour variation (abrash) and depth prized in fine rugs. The gentle shifts in hue across a field of "single" colour create a living quality that harmonises beautifully with restrained, sophisticated interiors. The time cost is substantial, but the visual reward is a depth no rushed process can replicate.

Scale and complexity: estimating the hours

A simple framework helps understand the time commitment: the approximate number of knots in a rug equals its area multiplied by its knot density. The number of working days required then equals the total knots divided by knots tied per day (which varies with weaver expertise and team size, but could range from 10 to 30 knots per minute).

Returning to our earlier example: a 6 square metre rug with 500,000 knots per square metre contains approximately 3 million knots. If a weaver averages 10,000 knots per day, this requires 300 working days. Doubling either the area or the density effectively doubles the required labour.

This calculation provides only a baseline. Design intricacy adds further time for pattern consultation and precision work. Stop-start sequences for error correction or colour changes interrupt flow. Finishing processes like pile trimming, washing, stretching, and edge finishing add days or weeks even after the weaving itself is complete.

The making sequence: where time is invested

A complete handmade rug progresses through distinct stages, each contributing to the overall timeline:

- Design and cartoon preparation establishes the pattern, with detailed mapping translating artistic vision into specific knotting instructions.

- Yarn preparation and dyeing creates the palette, with material processing and colour development requiring weeks or months for natural dyes.

- Warping and loom setup builds the foundation, with careful tensioning ensuring structural integrity for the months of weaving to come.

- Knotting and weaving form the primary labour investment, with consistent days, weeks and months at the loom building the piece knot by knot.

- Trimming and pile shearing creates an even surface, with selective cutting highlighting pattern elements through texture.

- Washing and drying sets the fibres, develops lustre, and stabilises colours, sometimes requiring multiple gentle cycles.

- Final stretching and edge finishing secures the structure and completes the perimeter for durability.

Quality control occurs at each stage, with inspections for alignment, knot regularity, and pattern clarity introducing deliberate pauses that prevent compounding errors.

Regional time signatures: Persian and other traditions

Different rug-making regions have distinctive approaches that influence production timelines. Persian carpet weaving centres like Tabriz, Isfahan and Kashan often pursue higher knot densities, incorporate silk detailing, and feature finely drawn curvilinear work - all choices that extend production time considerably. The resulting pieces typically display extraordinary detail and precision, with complex medallions and articulated borders.

By contrast, many Anatolian or Central Asian traditions favour bolder motifs and lower knot densities, allowing faster production. Turkish Oushak rugs or their Indian-made reproductions, for example, typically use a more open knot structure that accelerates weaving while still achieving sophisticated design impact through subtle colour variation and thoughtful proportions.

These regional choices translate into distinct aesthetic signatures. Persian rugs often serve as intricate focal points in a room, rewarding close inspection with remarkable detail. Anatolian pieces frequently offer rich abrash and tonal depth that create a quieter presence while still anchoring a space with warmth and patina.

Skill, teams and pace: experience matters

The weaver's expertise significantly influences both pace and quality. Seasoned artisans maintain consistent tension across the piece, read pattern cartoons efficiently, and maintain pattern fidelity with fewer reference pauses. This accumulated skill reduces rework while preserving meticulous detail.

Workshop dynamics also affect timeline. Multiple weavers on a broad loom can compress calendar time, but require careful coordination to maintain seamless pattern continuity across the piece. Each weaver must match tension and knot density with colleagues to prevent distortion or visible seams.

Throughout the tradition, accuracy and consistency take precedence over speed. Master weavers understand that rushing compromises the very qualities that define handmade excellence - even pattern distribution, proper knot seating, and the subtle rhythm that gives each piece its character.

Why time adds value

The months or years invested in creating a handmade rug directly translate into qualities impossible to replicate through accelerated processes. The slow building of thousands upon thousands of knots creates structural integrity that can withstand generations of use. The patient development of natural dye nuance yields a living colour palette that evolves beautifully with age rather than fading.

This deliberate pace connects today's pieces with centuries of tradition. When you walk across a handmade rug, you're experiencing the culmination of countless hours of focused human attention—a quality increasingly rare in our instant-gratification world. The time horizon for handmade rug creation isn't a delay or inconvenience, but rather an inherent and essential part of what makes these pieces endure both physically and aesthetically.

They stand as a reminder that some things cannot be rushed without fundamental compromise. In the quiet strength of each knot lies the value of patience, tradition, and the human touch that creates objects worthy of becoming tomorrow's heirlooms.